Some Known Facts About Aws Cwi.

Table of ContentsGetting My Aws Cwi To WorkNot known Details About Aws Cwi Fascination About Aws CwiSome Known Questions About Aws Cwi.7 Simple Techniques For Aws Cwi

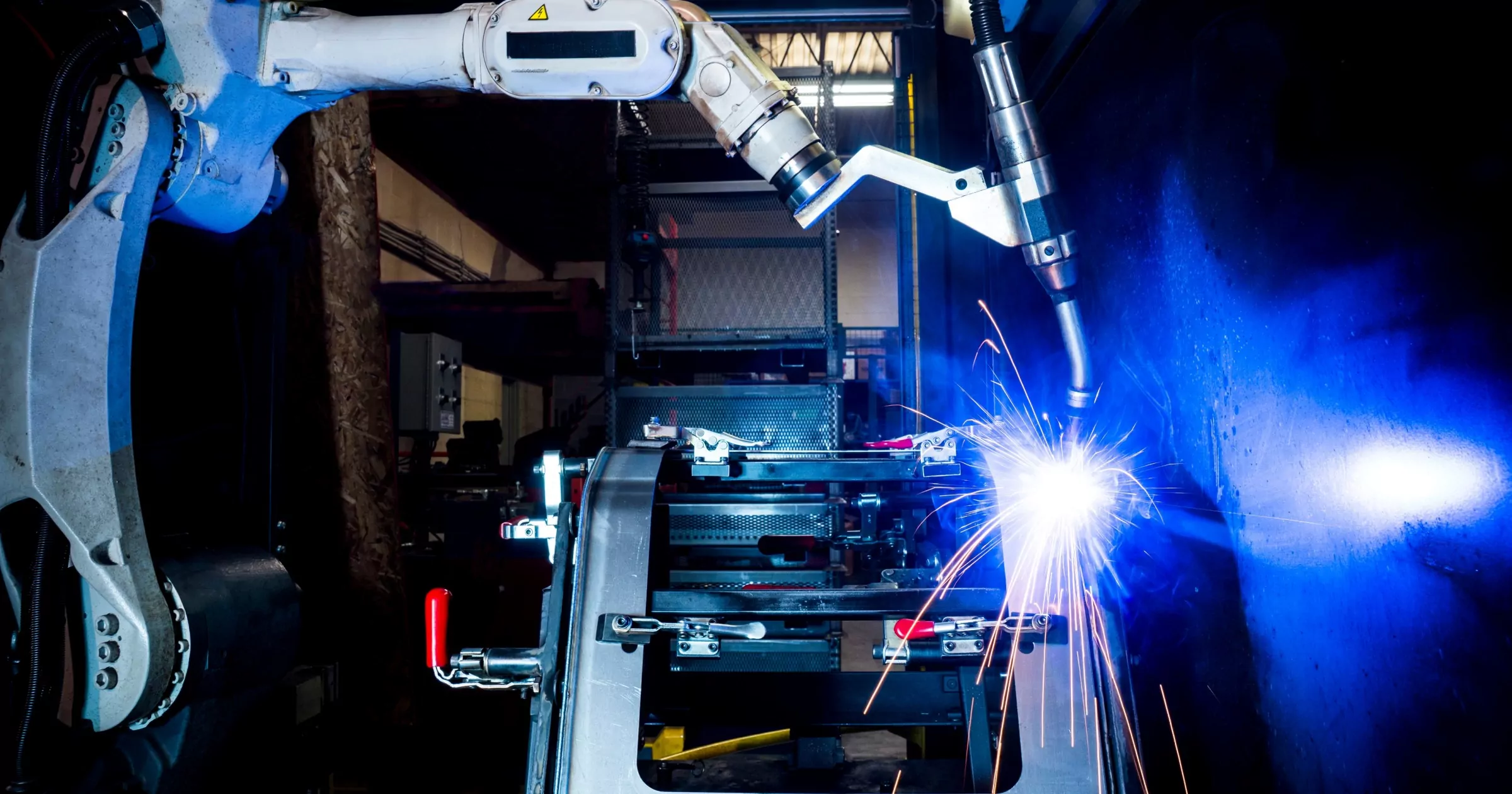

Third-party top quality control evaluation of steel manufacture fixate welding inspection, along with evaluation of bolting and painting of structural steel. KTA's steel assessors provide Top quality Control (QC) assessors to supplement maker's/ specialist's internal QC staff and on projects that mandate keeping the solutions of a qualified inspector (e.g., CWI) utilized by an independent examination firm.Inspectors conduct visual evaluations of product for conformance with the accepted specifications, plans and codes, in addition to confirmation of Certified Material Test Records (CMTR) for materials used. Products and parts are observed at vital factors along the manufacturing procedure in both steel mills and steel construction stores. KTA's certified welding examiners additionally witness welder and welding procedure certification tests as applicable to the extent of the task.

Steel manufacture examination solutions additionally routinely include doing non-destructive screening (NDT), also called non-destructive evaluation (NDE), consisting of Magnetic Bit Evaluating (MT), Ultrasonic Screening (UT) and Liquid Penetrant Evaluating (PT) (Weld Inspection). Inspections take place in steel mills and construction shops throughout the United States and on-site in the field and include all varieties of frameworks consisting of bridges, stadiums, buildings, towers, poles, and indication frameworks

Not known Incorrect Statements About Aws Cwi

KTA offers assessment solutions for the manufacture of bridge girders, bearings, grid deck, indication structures, light and website traffic poles, pedestrian bridges, and other highway components. KTA additionally offers these solutions for manufacture of architectural steel for structures, storage tanks and pipes. KTA's evaluation services include finish inspections covering surface area preparation, painting, galvanizing, and metalizing.

KTA's ideology is to respond promptly to clients' demands, match the right assessor to the job, and offer the requisite documentation. KTA has the assistance employees to offer technical consulting to the field personnel and to the customer. KTA has specialists readily available to get in touch with on welding, NDT and coverings.

FST Technical Solutions is your worldwide partner in the Semiconductor and Pharmaceutical Industries! Our settings include benefits such as medical, oral, vision, life, 401(k) with company match, PTO, paid vacations. Come join an awesome group in an exciting, quick paced, and ever-growing sector! We are looking for a CWI's and/or NDT Degree II licensed Welding Inspectors from in and around the Lithia Springs, GA area! Regional location candidates are encouraged to use yet this position is open to tourists with mobilization and month-to-month daily for those living outside the area.

Little Known Questions About Aws Cwi.

Semiconductor, Customer Products, Bio & Biopharmaceutical, and so look these up on. Suitable prospect will certainly have high pureness piping examination experience. Present AWS certs are preferred. CWI's and NDT Degree II's highly motivated to use.

Pro QC's third-party welding evaluation services include: Document Testimonial Witness Inspections Visual Inspections Dimensional Inspections Non-Destructive Testing (NDT) Others Our welding evaluation records are delivered within 1 day and document all inspection points relevant to high quality, consisting of all determined weld blemishes and electronic pictures (Welding Inspector) (https://www.video-bookmark.com/bookmark/6408477/aws-cwi/). Pro QC's group of assessors delivers third-party welding evaluations around the world, in China, India, Indonesia, Malaysia, Thailand, Vietnam, Singapore, South Korea, Turkey, UAE, Jordan, Egypt, South Africa, Morocco, Algeria, Tunisia, France, Germany, Italy, Czechia, Hungary, Spain, Sweden, Portugal, the Netherlands, Denmark, Norway, Finland, Belgium, the United Kingdom, Serbia, Greece, Romania, Bulgaria, Ukraine, Slovenia, Slovakia, Poland, Croatia, Russia, Lithuania, the USA, Mexico, copyright, Brazil, Peru, and a lot more nations

Assessment of the welding work is crucial for proper quality When your company is managing significant tasks with demands for third party independent welding examination, we offer superb welding witness evaluation services to verify that welding has been done according to the majority of applied welding criteria and requirements. AQSS carries out welding assessment solutions for clients from a range of sectors.

Excitement About Aws Cwi

Not complying with effectively certified welding treatments typically results in a weld of substandard quality, which can raise the manufacture's probability of failure under intended service problems. By evaluating for problems, our examiners can assist clients make sure that their welds satisfy appropriate requirements of quality control (Certified Welding Inspector). Weld evaluations are conducted for a number of factors, one of the most typical of which is to determine whether the weld is of ideal quality for its designated application

Our welding assessors have the needed certifications with years of experience with assessment and are acquainted with most applied welding standards and requirements. AQSS has CWI licensed inspectors.

The Single Strategy To Use For Aws Cwi

Typically, our assessors are checking for splits, pits, surface area pores, undercut, underfill, missed joints, and various other elements of the weld.

Samples can additionally be taken at intervals during the production process or at the end of the run. Devastating testing samples are specifically cut, machined, ground, and polished to a mirror-like coating. An acid etch is then applied to visually draw out the weld, and the example is after that checked under a microscopic lense.